Painting of Automative Steering

Challenges :

- Selection of grinder , the wheel and the paste as this had direct impact on the heat related deposits.

- Profile part resulting in complexities during programming.

- High precision and accuracy in grinding as the next process stage was plating.

Process qualified without a dust collection system which was considered as final BOM item during order supply

Solution: UR5e

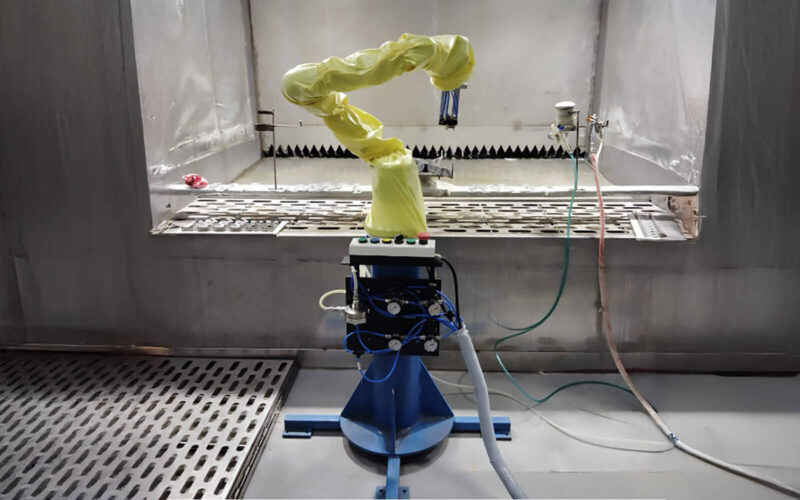

- Batch painting process using UR 5e cobot .

- Conveyor system and fixtures for the parts.

- Part variant set up and being supplied to KIA motors.

- Process operation done using the UR 5 e.

Process qualification of the painting process and the paint gun controls